Gas Bottle Wood Burner / Stove

How to recycle an old gas bottle into a wood-burner and cookerThis is a on going project that I will probably spend a couple of months doing, please check back here frequently as I will update this page with my latest progress. I would like to use an old recycled gas-bottle to make an efficient woodburner and cooker for as cheaply as I can. If the project goes well and it works, I will probably sand the whole thing and they spray paint it black using exhaust paint.

Project Materials

Im using an old gas-bottled which was dumped at our local reservoir. I decided to help the country-side and myself by recycling this piece of kit and see if I could make good use of it. Its always satisfying when materials for projects come free. The bottle looks a similar design to the one displayed on the right, just a bit older with a lot less paint.

Gas Bottle Specs

Gas Bottle Specs

- 50cm High

- 100cm Circumference

- 30cm Diameter

- 17.5KG Weight

The tank is now fully vented and depressurised! I've filled it with water to fully ensure all gas has been displaced.

Initial Design Ideas

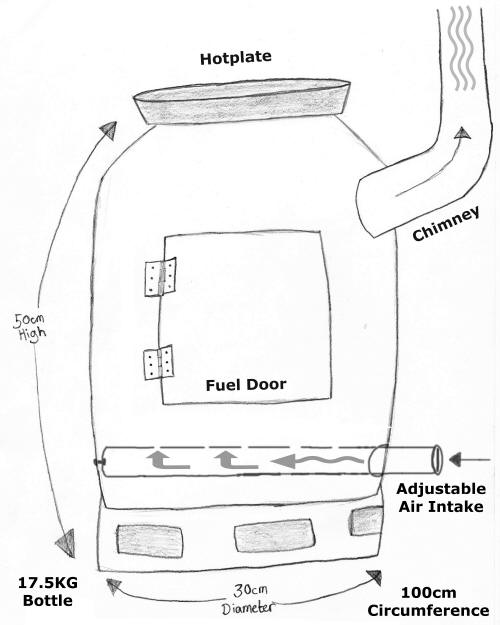

After running a few design ideas through my mind, this is the main one that im contemplating at the moment. Basically keeping the main shape of the gas bottle and utilising its original stand.

After running a few design ideas through my mind, this is the main one that im contemplating at the moment. Basically keeping the main shape of the gas bottle and utilising its original stand.

Now my drawing isn't the best as you can see so everything's not quite to scale, I think the air-intake pipe will be a lot smaller in comparison to the diagram's scale. A basic door will be cut into the front with a number of hinges, not sure what type yet. I will try to keep the door as air tight as possible. (You can click the image to enlarge it.)

A hole cut and then a good chimney with a bent neck welded on. The top of the bottle will be cut-off and a large, thick metal plate will be used as a hot-plate, possibly a disc-brake will be used for this, I'll have to see what I can scavenge. This hot-plate can then be used for cooking, with a pan on the go we'll have sausages cooked in no time!

The idea with the bottom 'adjustable air-intake' will be to control the strength and heat of the burn. I will try to keep the unit as air-tight as I can, the door will be the main challenge. The air intake will quite simply be a pipe with four or five holes drilled in, and then a larger hole on the outside with some form of controllable/adjustment on there, still to decide on what I'll use.

I will have some sort of grill to hold the fuel in between the fuel-door and the air-intake pipe, so that the fuel does not block the air-intake.

Click on the diagram to view a larger, full resolution diagram.

Work in Progress

Here's me working on grinding out the fuel-door for my wood burning stove. The dimensions I went for were:

18cm down vertically.

15cm across horizontally.

I had a 1mm thick cutting blade on the grinder to try and minimalism the amount of loss of metal in hope of using the metal-door that I cut out of the bottle, however I think even now there is too much loss and there will be a gap, I want to make it an air tight fit as possible to later have good control of air-flow. So I will be using a separate piece of sheet metal to make a door out of at a later date.

The work is going well so far, I have roughly cleaned up the edges of the cuts so far so they are not to sharp. Next I will need to decide on a size for my chimney and an appropriate hunk of metal for my hot-plate that will sit on top. Once I have decided on a chimney size I can cut the hole for that, and then providing I have found a hotplate I will prepare the bottle and joints for welding. I've got a disc for my grinder to clean off the paint etc. from the bottle. I don't have any experience in welding, Im pretty sure I wont be doing it myself (you never know!) so I'll probably get everything as ready as I can and then get a friend to do the welding.

Other Resources

http://www.bushcraftuk.com/forum/showpost.php?p=373641&postcount=6

Wood burns best when vented from above.

Coal burns best when vented from below..(on a grate).

AT ONES OWN RISK..I accept NO responsibility.

My IDEA is for a wood / oil burning stove. When heated, drip old engine oil onto a piece of (now hot) metal (tow ball?) in the centre of the fire. The rate of flow of oil controlled by a simple twist valve like on a water pipe to the washer which is situated away from the heater. The waste oil is to be from a reservoir, eg a 5Litre can or plastic bottle with whe top cut off.

The feed for the oil is via some brake pipe.

As the oil hits the tow ball or similar, it splatters/vapourises giving rise to a hotter clean burn ..hopefully.

Thoughts anyone?

Have you seen the crazy complex flowering elbow design stove (downwards burning with a separate heating unit bit)?? I would like to know what you make of it??

Phil

thanks

chris

Email:

beccleskingfishers20@hotmail.com

Many thanks.

If you can email me I would be very grateful

r.higginsdg2@yahoo.co.uk

The heat output is quite amazing. Its a shme we can't use these for backpacking, it would provide such s nice end to the day! warm bivi, hot tea and toast.

Thanks for the idea.

Here is the youtube link:

http://www.youtube.com/watch?v=YLNZupbz9d0

I one day hope to finish it, I need to get round to learning some welding skills from my cousin. Keep checking back as there will be something new hitting NaturalBushcraft very soon!

What i would have done was cut the door for fuel lower with the door wider and fatter, and then on the top of the bootle put a hinge with a lock and have a grill in the middle of the bottle aswell as the hot plate on the top, but awesum idea fella

Joe

Having said that, these stoves are a great idea and I would certainly like to have a go at making one. A great article. Good luck!

It's only stupid if you don't know how to safely discharge the gas from these bottles. If you fill them with water and empty them they are safe to work with, you would be paranoid to think otherwise.

Why would someone do something like this? Maybe because it's a project? something new to learn? Skills to practice and try, fun to be had in the trying & testing and final use? Knowing that you've recycled numerous parts of junk and turned them into a functional/useful piece of kit that would have otherwise gone to landfill. It's a mentality like yours ("Cheap Chinese stoves .... justa few quid") that puts more broken crap into landfills.

Good luck. hope it works for you and lets all stop giving our hard earned money to these greedy energy suppLIARS who want us all to be at their mercy.

the old sistern so i built a decent wood stove it has 4" flue pipe and bottom inlet be low brick layer is a rotor off a car for air and to holes below loading door that 5/8 diameter bolts slide into for air adjustment any question on problems call 740 343 0119

im hoping to make a burner myself for my van. It seems natural to me that if you wantt a hot plate you just turn the bottle upside down,

Or is that a bad idea? why in that case?

Thank you.

Daniel.

I want to heat my hot tub with something similar and whilst surfing for info I cam accross this. I was think of coiling thin copper pipe inside the upper part of the chamber and pumping water through it> I have seen someone on you tube do it without a pump. Whilst I'm at it, I may as well go the whole hog and join another bottle on the side and have an oven (I say that on youtube too). Anyone got advice on any pitfalls etc.... Great info already on making efficient burner. Daz

Arnie is right, air from below will make the fire gutter and then go out with wood, though it works with coal. Better than an air pipe is a close-able hole in the door, just cut a semicircle out of the door, and bolt a bigger semicircle of metal over it to make an adjustable air vent. Fold one edge of the semicirlcle outwards so you have something to tap round with your poker. Sand in the bottom will work well to insulate the bottom.

If you want to cook on your stove then a flat top is better with the flue coming out of the top at the back. If the cooking surface is above the level of the flue it won't get very hot. Best bet is a baffle which directs the air up the front of the stove and along the underside of a flat hotplate to a flue (steel stink pipe?) welded on at the back. If you cut the top off the bottle, then cut it in half and drop it down into the stove you get a ready made baffle. Weld a flat plate on top. Plus its easier to get a good fit for your flue into a flat surface.

Also the proportions of your door look too high, smoke will likely come out of the top when you open the door. A low wide door will allow you to run the stove with the door open without smoke coming out.

Anyhow god luck!

Jug, don't use anything made of aluminium whatever you do- it can melt at the sort of temperatures you can get burning wood. A steel beer keg should work OK though, and I've seen burners big enough to heat a large marquee made from oil drums.

As someone with experience of woodburners, allow me to offer a few thoughts.

1. It is far better to feed air from above the combustion chamber than from below in a wood burner. This encourages a bed of hot ash and

improves output and efficency. (This is very differnt to coal which is fed

air from underneath) It may well be that the gap around the door is

sufficent, failing this an adjustable vent fitted in the upper section of the door would do.

2. To increase the combustion temperature, and again improve output and efficency insulate the base of the combustion chamber.

A 25mm piece of lightweight building block cut to shape is cheap and easy. Use an old handsaw for slicing

3. To increase the output to the hotplate, a thinner steel section,

say 4mm of flat plate rather than the old disc brake. Even better cut the cylinder lower down and have a larger plate welded.

So please could you help me and give me advice on how to remove the valve, The bottle i use is a 15KG (similar to the picture you have above.

Thanks

juggalo